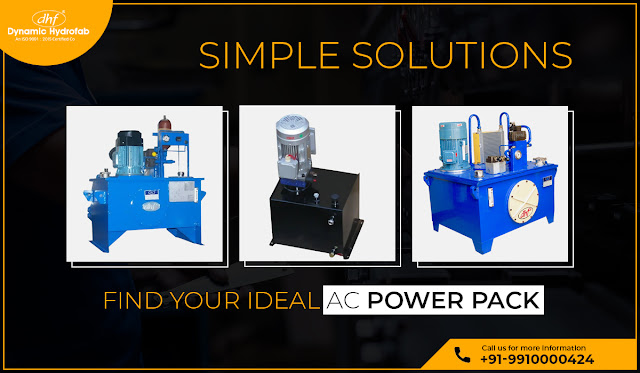

Simple Solutions: Find Your Ideal AC Power Pack

AC power packs are

widely used to power hydraulic systems. It's a reliable and efficient solution

for most industries. These power packs are key components in many fields,

driving hydraulic machinery and equipment with their necessary energy. Several

factors, including capacity, voltage, features, and reliability, must be

considered before you find the ideal AC power pack to meet your own needs.

This guide assists in that decision-making process by presenting the main

considerations when looking for an effective solution for AC Power Pack India.

After you start

considering an AC power pack, it is

necessary to evaluate your power needs. Such as the type of hydraulic equipment

to be operated, how much power it needs, and so on. Add up all your power needs

to ensure that any AC power pack you

select can handle the load properly, especially if you are using a

variable-frequency drive. An understanding of your power needs beforehand will

facilitate this process of choosing and prevent either having things that are

too weak or too strong.

Voltage

and Phase:

AC power packs are

available with multiple voltage and phase configurations to meet different

electrical systems. Determine which voltage and phase your present system can

cope with, or the specifications of hydraulic equipment you possess. Standard

voltage choices include 110V, 220V, 380V, and 440V; typical phases are

single-phase and three-phase. If you choose the right voltage and phase, then

both the compatibility and performance of the power pack ought to be assured.

Assess

Capacity and Flow Rate:

When selecting an AC power pack,

you should remember that capacity and flow rate are two important factors. The

word capacity refers to how much hydraulic fluid can be stored in the power

pack at most; flow rate indicates the quantity of fluid released in a given

period.

Evaluate

built-in features:

Several built-in

features turn up on today's AC power

packs, designed to improve functionality, make the equipment safer, and

improve the efficiency of operation. Look for features such as pressure gauges,

overload protection, thermal protection, and variable pressure settings. These

features provide a fine degree of control, provide the means to monitor the

state of the hydraulic system, and safeguard its functioning.

Review

Portability and Installation Options:

Check the portability

and installation requirements of your power pack. If you have to move or locate

it in different places, are there any special restrictions on this? Look for

designs that allow for easy transport and installation and are compact and

lightweight. Furthermore, examine the mounting options and whether they are

compatible with your workspace or the equipment's layout.

Prioritize

durability and reliability:

When you are choosing

an AC power pack for industrial use, your primary consideration should be

durability and reliability. Look for bulky, powerful units that are built of

strong parts and cobbled together with the minimum number of assembly lines.

Research well-known brands that have become famous over time for producing

hard-core yet incredibly reliable power packs that keep plugging away at top

performance far beyond any expectations one might have had when they first

bought them.

Also Read:- Power up With Precision: AC

and DC Power Packs in India

Assess

Cost and Value:

Also, check what the

value of that AC power pack is. Although cost is important to some extent,

concentrate on the overall value of your AC power pack. Compare prices between

different manufacturers or suppliers by such criteria as quality, features,

guarantees, and post-sales service. Choose an AC power pack or DC Power Pack that is value for money

and delivers performance like that which you expect from your investment.

Remember, too, that a superior power pack will save you money in the long run

because of its higher efficiency and reliability.

Conclusion:

The choice of AC power pack that best suits your

particular style of work comes from carefully gauging all these elements: power

requirement, voltage, capacity, characteristics, stability, safety, and

purchase price. When you take these all together into account and in line with

your operational needs, you will be able to choose a Compact Power pack that meets standard NBR 12 and gives you

constant high performance with reliable, low-cost operation for the whole

hydraulic system.

Post a Comment